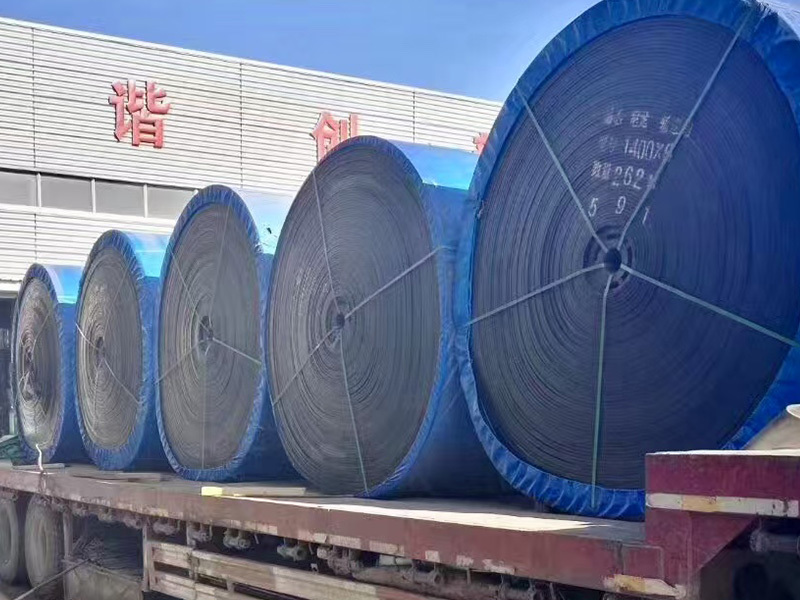

What are the processing methods for conveyor belts?

Conveyor belts are commonly used for material handling in industrial production. However, due to friction, wear, and other factors during prolonged use, conveyor belts are prone to "derailment," leading to decreased production efficiency and even affecting work safety.

This problem can be solved by installing guide rails on the conveyor belt.

Guide rails are small, protrusion-like devices that keep the conveyor belt in its correct position. Their advantages are mainly reflected in the following three aspects:

First, guide rails can reduce the occurrence of conveyor belt "derailment." Over time, the rubber material of the conveyor belt becomes soft due to wear and aging, causing the conveyor belt to "deviate." Guide rails can maintain the conveyor belt's correct position by securing it.

Second, guide rails can improve production efficiency. Using guide rails reduces the deviation caused by belt misalignment, ensuring the conveyor belt's accuracy. This reduces waste and improves production efficiency.

Guide rails can improve work safety. When a conveyor belt deviates, safety accidents are easily triggered. Installing guide rails effectively reduces the occurrence of conveyor belt deviation, ensuring work safety

TAG:

Previous

Previous:

Related Posts

What are the processing methods for conveyor belts?

Message

We will contact you within one business day. Please note your email address.

Fast Navigation

Connection

Whatsapp/Tel: +86 15176393888

E-mail: Darren@cnconveybelt.net

Add: Chengxi Industrial Zone, Li County, Hebei Province, China