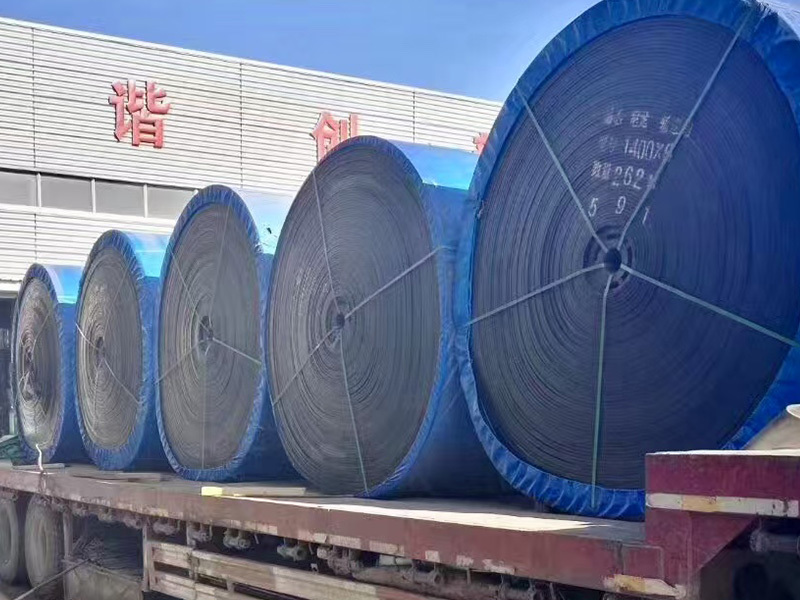

Applications of idler rollers

Idler rollers are widely used in mining, metallurgy, chemical, grain, port, power, and building materials industries, meeting the needs of various working conditions:

Mining: Conveying coal, ore, and other bulk materials requires high load-bearing capacity and wear resistance.

Port: Long-distance, high-angle conveying requires anti-deviation and impact resistance.

Chemical: Corrosion-resistant idler rollers adapt to acidic and alkaline environments.

Grain: V-shaped idler rollers improve conveying efficiency and reduce material spillage.

Power: Coal conveying systems in power plants require buffer idler rollers to protect the conveyor belt.

TAG:

Related Posts

What are the processing methods for conveyor belts?

Message

We will contact you within one business day. Please note your email address.

Fast Navigation

Connection

Whatsapp/Tel: +86 15176393888

E-mail: Darren@cnconveybelt.net

Add: Chengxi Industrial Zone, Li County, Hebei Province, China