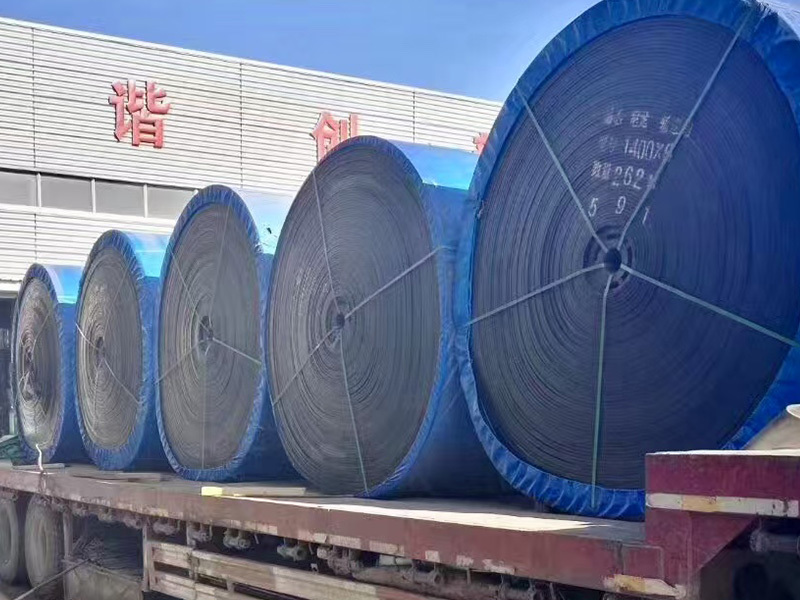

Classification, characteristics, and applications of patterned conveyor belts

Patterned conveyor belts are commonly used conveyor belts with wide applications across various industries. Patterned conveyor belts have many classification characteristics; their main classification characteristics and uses will be introduced below.

Classification Characteristics of Patterned Conveyor Belts

1. Pattern Shape: The pattern shapes of patterned conveyor belts can be classified into V-shaped, trapezoidal, U-shaped, fishbone-shaped, circular, etc. Different pattern shapes have different uses in different working environments.

2. Pattern Depth: The pattern depth of a patterned conveyor belt determines its application. Generally, the deeper the pattern, the greater the weight it can carry.

3. Pattern Spacing: The pattern spacing of a patterned conveyor belt is also one of its classification characteristics. The larger the pattern spacing, the better the drainage of the conveyor belt.

Applications of Patterned Conveyor Belts

1. Mining Industry: Patterned conveyor belts are widely used in the mining industry to convey ores, coal, and other materials.

2. Construction Industry: Patterned conveyor belts are also widely used in the construction industry. They can be used to convey concrete, sand, bricks, and other construction materials.

3. Metallurgical Industry: In the metallurgical industry, patterned conveyor belts are mainly used for conveying in processes such as sintering, casting, and heat treatment.

4. Chemical Industry: Patterned conveyor belts are also widely used in the chemical industry. They can be used to convey various chemical raw materials, such as powders and granular materials.

In summary, the classification characteristics of patterned conveyor belts determine their applications. When selecting a patterned conveyor belt, it is necessary to select one based on the specific working environment and requirements.

TAG:

Next

Related Posts

What are the processing methods for conveyor belts?