Classification and Characteristics of Rollers

Classification by Application

Troughing idlers: Used in the carrying section to support the conveyor belt in a trough shape, increasing the material carrying area and preventing spillage.

Parallel idlers: Used in the return section or for conveying piece goods, providing stable support.

Impact idlers: Installed below the receiving point, absorbing impact force through rubber rings or elastic materials.

Self-aligning idlers: Including conical self-aligning idlers and spiral self-aligning idlers, automatically adjusting the conveyor belt position to prevent deviation.

Return idlers: Support the unloaded conveyor belt return, reducing friction.

Classification by Material

Steel idlers: Such as carbon steel idlers and stainless steel idlers, high strength, suitable for heavy loads or corrosive environments.

Plastic idlers: Such as polymer idlers and nylon idlers, light weight, corrosion resistant, suitable for light loads or special working conditions.

Ceramic idlers: Wear-resistant, high-temperature resistant, suitable for high-wear environments.

Composite idlers: Such as carbon fiber composite idlers, combining the advantages of multiple materials to improve overall performance.

TAG:

Related Posts

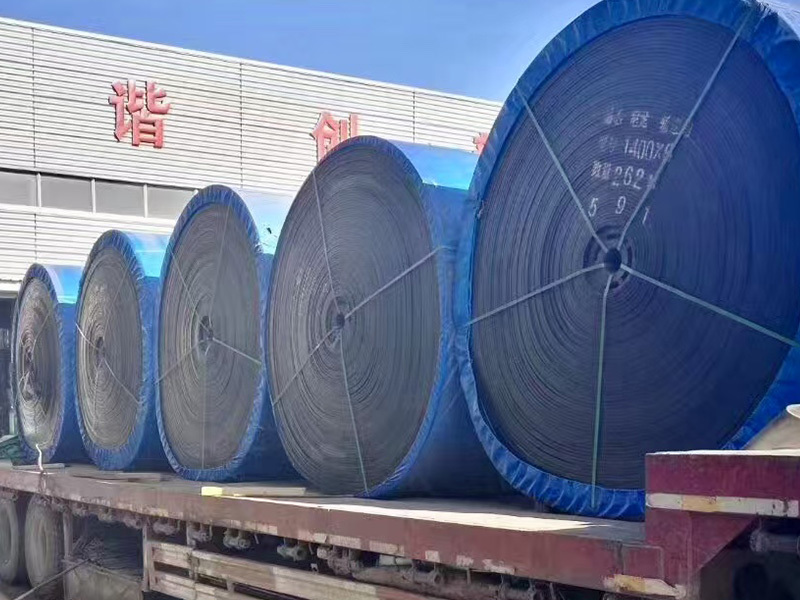

What are the processing methods for conveyor belts?

Message

We will contact you within one business day. Please note your email address.

Fast Navigation

Connection

Whatsapp/Tel: +86 15176393888

E-mail: Darren@cnconveybelt.net

Add: Chengxi Industrial Zone, Li County, Hebei Province, China